Products

Fire Fighting Equipment with Fire Hose with Fire Coupling

Product Introduction

fire hose is a hose used to carry fire-retardant liquids such as high-pressure water or foam.

This product uses polyester filament as warp and weft yarn raw material to weave strip blank, make water strip can bear higher working pressure, then stick polyurethane layer of certain thickness on its inner wall lining, in order to improve the sealing performance of water strip, and inner wall is smooth, the utility model has the advantages of small water resistance, high pressure resistance, high temperature resistance, oil resistance, corrosion resistance, bending resistance, light weight, etc.

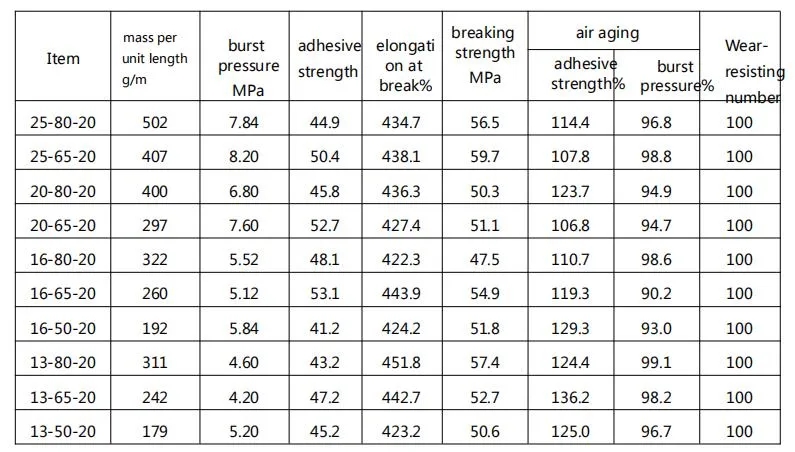

This product conforms to GB6246-2011″fire hose” standard.

Application

This product is mainly used for fire fighting, industrial and mining enterprises, petrochemical oil depots, agricultural, construction and other water, drainage and irrigation, pipeline connection.

Usage

1.Before use, please check whether the working pressure is consistent with this product model;

2.When in use, the water belt is released, one end is connected with fire hydrant or water supply equipment such as fire pump, fire truck, and the other end is connected with equipment such as fire water gun or water cannon, so as to operate and use the target to achieve the desired effect;

3.After use, it should be washed and dried, rolled up and stored in a cool and dry place.

Pay attention when use

1.Laying should avoid sudden twists and turns, after filling water to avoid forced dragging on the ground to prevent reducing water resistance, pressure performance or off, should not v-shaped drag water belt, to avoid abrasion water belt;

2.Cotton or linen water strips should be used in areas where there may be flame or strong radiant heat;

3.Climb the water strip when laying hook with the water belt;

4.Through the railway should be under the track through, through the road, should pad on the water belt bridge;

5.This product is strictly prohibited in use on sharp objects drag, special attention to avoid nails, glass pieces and other sharp contact, so as not to damage the woven layer;

6.Avoid contact with oil, acid, Alkali and other corrosive chemicals, pay attention to moisture;

Maintenance

1.On long-term use of high-pressure water belt to regular inspection, inspection items include: Skin Wear and aging degree, joint wear degree. A weekly check is recommended.

2.Storage should be single-layer roll up the stand drain belt rack. Long-term storage should be turned twice a year or exchange fold once. With the water belt to avoid friction with each other, if necessary, to exchange hem.

3.Water belt should be used after the surface cleaning work in a timely manner, the removal of water belt surface corrosive substances.

4.Do not store your hose outside. Avoid aging and pollution of water belt caused by sunshine and other factors.

5. It is not recommended to repair the broken water belt. If found, replace it immediately to avoid accidents and injuries.